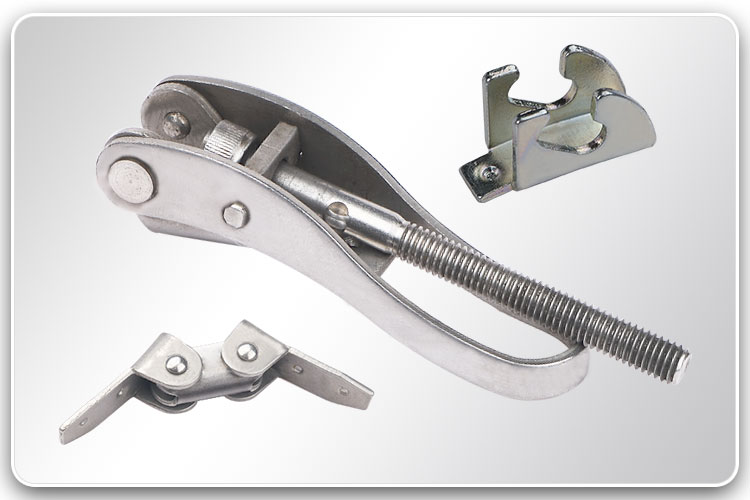

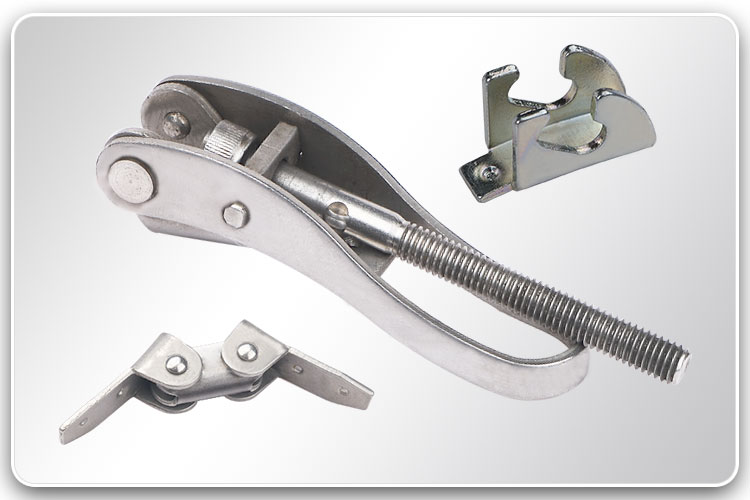

वर्णन

स्पॅनरिंगसाठी स्टॅम्पिंग पार्ट्स क्लॅम्पिंग रिंग उत्पादनांसाठी महत्त्वपूर्ण घटक आहेत. प्रत्येक क्लॅम्पिंग रिंगमध्ये कमीत कमी 4 काठीचे भाग असतात. स्पॅनरिंगसाठी स्टॅम्पिंग पार्ट्स क्लॅटिंग रिंग भागांसह बट वेल्डिंगद्वारे थेट एकत्र केले जातात आणि त्यानंतर मजबुतीकरणासाठी हँड वेल्डिंग केले जाते.

The essential control points for the Stamping Parts for Spannring are the tolerance for the slots and the height of the butting welding bulges. The slot contact point with the turning parts arm need to be pressed in, making sure that the turning parts can rotate freely while being held in place. The definite and consistent height of the welds is the guarantee for high welding quality.

Auwell has more than 15 years of experience in manufacturing and supplying Stamping Parts for Spannring product, at this moment, 100% of products exported to Germany for our distinguished clients. Equipped with a progressive die machine, Auwell can produce Stamping Parts for Spannring parts efficiently for cost-effective reasons. Progressive stamping is the guarantee of quality consistency.

By using optimized technology and programming, our saddle for clamping rings products have been proven as excellent in quality at an affordable price. Auwell is proud of its high productivity for producing these products in a cost-effective way.

Following video demonstrates our professional way in saddle for clamping rings production:

The Stamping Parts for Spannring products displayed are custom made exclusively for our distinguished clients. We are happy to offer competitive price to all inquiries from potential clients.

तांत्रिक माहिती

-Material: ST12, ST37,

Q235B, Stainless steel 304, 316L or upon request

-काठीची जाडी: 2.5 मिमी

-पृष्ठभाग: हलके तेलाचे रस्टप्रोटक्शन

-Package information:

Available upon request

Advantages

-श्रीमंत अनुभव

More than 15 years of

experience in saddle for clamping rings products development and production, especially

to the European markets. With solid understanding of the material, technical

and quality standards worldwide.

-वेगवान वळण

Generally, we provide a

quotation within 3 working days. Combining the latest manufacturing

technologies and facilities, Auwell can provide fast prototypes for saddle for

clamping rings in just 3 weeks for saddle parts.

-Comprehensive Solution Provider

Auwell provides

comprehensive services for saddle for clamping rings projects starting from

designing, through prototyping, tooling/fixture development, sampling, mass

production, and to logistic and post-sale support.

-कठोर QC धोरणे

सर्वात कठोर क्वालिटी पॉलिसी सामग्री नियंत्रणापासून सुरू होते आणि त्यानंतर अंतिम-शिपमेंट तपासणीपर्यंत घेतली जाते. मटेरियल प्रमाणपत्रांमध्ये गिरणी प्रमाणपत्र, तृतीय पक्षाचे रासायनिक घटक आणि यांत्रिक मालमत्ता अहवाल तसेच विनंतीनुसार रॉएचसँड पोहोच अहवाल समाविष्ट करतात. आम्ही आमच्या प्रक्रियेची रचना करतो, उत्पादनापूर्वी फ्लो चार्ट्सँड कंट्रोल प्लॅन तयार करतो आणि हे सुनिश्चित करतो की सर्व QC प्रक्रिया ISO9001-2015 च्या आवश्यकता आणि ड्राइंग वैशिष्ट्यानुसार आहेत.

-लवचिक पेमेंट टर्म

Tooling payments need to

be pre-paid. For mass production, we offer flexible payment terms, reasonable

credit terms will be given, the client only pays when they are happy with the

product they received. For long-term projects, we offer call-off inventory

services for fast delivery requirements.

संबंधित उत्पादने

Fast Connector for Clamping Rings

Fast Connector for Clamping Rings

रॅली क्लॅम्पिंगसाठी पार्ट्स बदलणे

रॅली क्लॅम्पिंगसाठी पार्ट्स बदलणे

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик